Birati, Kolkata, West Bengal

Dry Veneer Preparation and Composing

Leading Manufacturers, Exporters and Wholesaler of Automatic Veneer Roller Dryer, Core Veneer Composer Machine, L type Panel Composer Machine and Multi Layer Mesh Belt Dryer from Kolkata.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Color | Blue |

| Automatic Grade | Automatic |

| Certification | CE Certified |

| Voltage | 220V, 440V |

| Type | Veneer Dryer |

| Country of Origin | India |

Preferred Buyer From

| Location | Worldwide |

This is Semi-Automatic Veneer Feeder for Dryer.

The Veneer palletstobe Placed by Fork Lift to 2 Nos. Scissor lifts at Auto - Feeder end. Once the veneer pallets Placed on Scissor Lift, 3 no worker can start Veneer feeding. Once the top pressing roller is pressured down on the feeding roller by pneumatic cylinder,the Automatic Veneer Feeder Unit puts the veneers in respective decks. The Veneer Feeder unit moves up and down by help of Hydraulic Cylinders stops at desired levels by the help of Sensors / encoders PLC+HMI of the Decks. Power requirement: 2 Hp for Feeder, 15 Hp for Hydraulic Station &2 Nos. Scissor Lifts. Suitable for Veneer thickness 1–4mm. Machine Length; 4600mm, Width: 1200mm, Height: 1490mm.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Warranty | 1year |

| Certification | CE Certified |

| Usage/Application | Veneer Industry |

| Driven Type | Electric |

| Material | Stainless Steel |

| Finishing | Polished |

Preferred Buyer From

| Location | Worldwide |

Salient Features of Core Composers

• HMI-PLC controlled & operated by 1 operator saves manpower.

• The entire system servo-motor based & controlled through multiple sensors to achieve higher efficiency and perfection in veneer joining.

• Saving of manpower by 70% from veneer repairing, 80% from core veneer joining & Putty work manpower saving 50%.

• Heating & cooling System for glue. Air Conditioning system for glue cooling down.

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Automatic |

| Voltage | 220V |

| Type | L type Panel Composer Machine |

| Warranty | 1year |

| Country of Origin | India |

Preferred Buyer From

| Location | Worldwide |

Salient Features of Core Composers

• HMI-PLC controlled & operated by 1 operator saves manpower.

• The entire system servo-motor based & controlled through multiple sensors to achieve higher efficiency and perfection in veneer joining.

• Saving of manpower by 70% from veneer repairing, 80% from core veneer joining & Putty work manpower saving 50%.

• Heating & cooling System for glue. Air Conditioning system for glue cooling down

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Iron |

| Finishing | Polished |

| Power Source | Electric |

| Automatic | Automatic |

| Color | Blue |

| Voltage | 220V |

| Type | Belt Dryer |

| Country of Origin | India |

Preferred Buyer From

| Location | Worldwide |

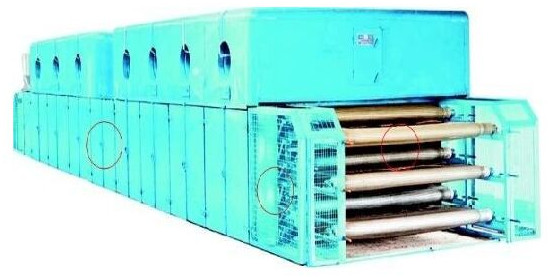

Band Dryer with SS-304 Band and Auto Alignment of Board

Continuous conveyor Band Dryer is Ideal for drying thin Face Veneer, Sliced / Peeled Decorative Veneers, PF Resin Impregnated Core Veneers, Bamboo Mat/ Curtain etc. The machine has stainless steel Bands or

Conveyors for rust-free operation. Each deck has a set of pressing Band to keep the dried material in portion and prevent wear and tear. Double set of Jet Boxes provide uniform drying all along the length of the Dryer.

The Dryer has extended feeding section to enable proper arrangement of the materials during feeding. The Dryer is supplied with specially designed Alloy Fan and Dyno Drive for variable feed speeds and Band

Tensioning with Auto Alignment System along with separate desk Feeding & Discharge Conveyors. Standard Models of Band Dryers are available in 4 section 3 deck, 5 section 3 decks, 8 Section 3 deck, 10 Section 3 deck. Technical Data – 10’ / 2750mm Standard Band Width MESH / BAND Dryer for Thin Veneer